In the world of wallet manufacturing, bonding might not be the most visible process, but it plays a critical role in ensuring the structural stability, durability, and visual appeal of the final product. Whether you're producing classic leather wallets or modern minimalist designs, selecting the right wallet bonding technique is essential for long-term product performance and customer satisfaction.

As materials and design requirements continue to evolve, so too have the bonding methods used in OEM wallet production. From traditional cold gluing and hot melt adhesives to advanced heat press and ultrasonic bonding techniques, today’s manufacturers have a range of solutions to meet both aesthetic and functional goals.

In this article, we’ll explore five common wallet bonding techniques used in professional production environments. Whether you're sourcing for a custom leather wallet manufacturer, developing new product lines, or optimizing your supply chain, understanding these bonding methods will help you make smarter, more cost-effective decisions.

Technique 1: Cold Glue Bonding

Application Scenarios: Classic genuine leather wallets, bonding between card slots and outer shell

Suitable Materials: Natural leather, PU leather, microfiber leather

Process Description:

Cold glue bonding uses eco-friendly adhesives without heat, making it one of the most reliable and material-safe techniques in wallet production. It is especially suitable for large-area bonding such as attaching the inner lining or securing full-size leather panels. This method ensures strong adhesion while preserving the natural texture and structure of leather, which is crucial in high-end wallet manufacturing.

The adhesive is manually applied with precision tools or brushes, followed by pressing and curing under moderate pressure. Since the glue does not require heat to activate, it avoids shrinkage, discoloration, or warping—issues that can occur with heat-sensitive materials like PU or microfiber leather.

Cold glue bonding is commonly used in the assembly of classic leather wallets, including bifold, trifold, and long wallets. It’s ideal for attaching card slots, bill compartments, and decorative leather overlays to the main wallet body.

This process is widely preferred by OEM and custom wallet manufacturers for its clean finish, dependable strength, and versatility across a wide range of leather types.

Technique 2: Hot Melt Adhesive

Application Scenarios: Structural fixing, lining bonding, simple wallet designs

Suitable Materials: Synthetic leather, fabric wallets

Process Description:

Hot melt adhesive is a thermoplastic glue that becomes liquid when heated and solidifies upon cooling. This quick-setting method is widely used in wallet manufacturing for securing internal structures and attaching linings. It offers fast bonding speed and is suitable for automated production lines.

Because of its strong initial tack, hot melt adhesive works well with synthetic leather and fabric materials, making it ideal for casual or budget-friendly wallets. The process improves production efficiency but may be less flexible than cold gluing for delicate leather.

OEM manufacturers favor this technique for mass production where speed and cost control are priorities, especially on simpler wallet designs.

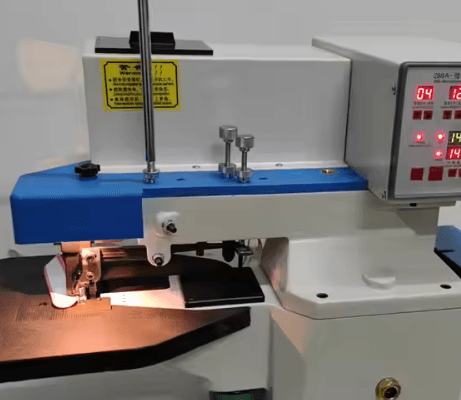

Technique 3: Heat Press Bonding

Application Scenarios: Modern minimalist wallets, vegan leather card holders, eco-friendly TPU products

Suitable Materials: TPU, PVC, PU, PEVA and other synthetic materials

Process Description:

Heat press bonding uses controlled heat and pressure to fuse wallet materials without stitching or glue residue. This technique creates a seamless, waterproof, and clean finish that is highly valued in contemporary wallet designs, especially those focusing on sustainability and durability.

The process involves placing wallet components between heated plates, which activate adhesives or melt material surfaces to bond tightly together. This method eliminates needle holes, reducing the risk of water infiltration and enhancing overall product longevity.

Widely adopted by custom wallet manufacturers focusing on innovative materials, heat press bonding delivers a sleek look with reliable strength, perfect for large-scale OEM production with modern aesthetic demands.

Technique 4: Contact Cement

Application Scenarios: Heavy-duty wallet structures, multi-layered designs

Suitable Materials: All leather types, thick materials, composites

Process Description:

Contact cement is a strong adhesive applied to both bonding surfaces, left to dry until tacky, then pressed firmly together. This method provides an extremely durable bond suitable for wallets requiring high strength and long-lasting wear.

Due to its high bonding power, contact cement is often used in premium wallet manufacturing for attaching thick leather layers or reinforcing stressed areas. However, it requires careful handling and proper ventilation due to strong fumes.

While less common in mass production, OEM manufacturers choose contact cement when product durability and structural integrity are top priorities.

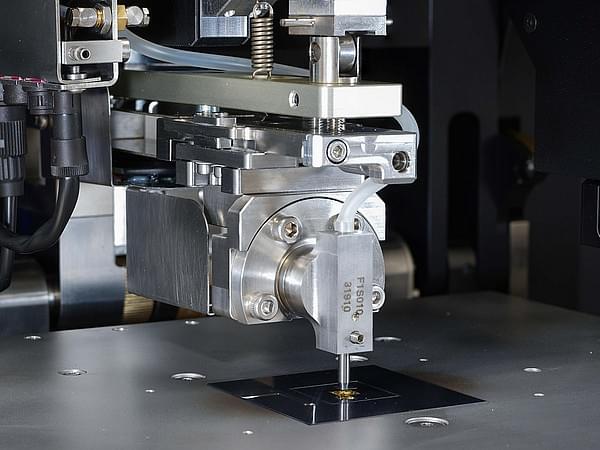

Technique 5: Ultrasonic Bonding

Application Scenarios: Eco-friendly wallets, seamless modern designs

Suitable Materials: TPU, PE, non-woven fabrics

Process Description:

Ultrasonic bonding uses high-frequency vibrations to generate heat through friction, fusing wallet materials without the need for glue or stitching. This innovative method offers a clean, durable, and environmentally friendly bonding solution.

Ideal for synthetic and recyclable materials, ultrasonic bonding creates strong, waterproof seams with minimal material damage. It’s widely adopted in custom wallet manufacturing focused on sustainability and speed.

Though requiring specialized equipment, this technique enables fast production cycles and aligns with growing demand for eco-conscious wallet products.

When to Choose Which Bonding Technique?

Selecting the right bonding technique depends on factors such as design complexity, cost budget, durability requirements, and environmental standards. For brands aiming at the high-end market, a combination of handcrafted cold glue bonding and heat pressing is recommended to ensure superior quality and refined appearance. On the other hand, for fast mass production, techniques like hot melt adhesive and ultrasonic bonding offer greater efficiency and speed.

At Sunteam, we apply these bonding methods strategically in our wallet manufacturing to meet diverse client needs. For our premium wallet lines, we emphasize precision craftsmanship using cold glue and heat press techniques, guaranteeing durability and an elegant finish. Meanwhile, for larger production runs, Sunteam utilizes hot melt and ultrasonic bonding to maintain quality while achieving timely delivery.

Conclusion

The bonding technique significantly affects the quality, appearance, and brand value of wallets. Choosing the right technology is essential to ensure wallets are durable and competitive in the market.

Feel free to contact us to learn more about wallet manufacturing details and customized solutions.

Looking for a reliable OEM wallet manufacturer with strong bonding techniques? Contact us today for custom solutions.