Bonded leather is a popular leather alternative that combines leather scraps with synthetic materials to create a product that looks and feels like real leather. As a wallet manufacturer, you may wonder about its durability, cost, and suitability for crafting high-quality wallets compared to genuine leather.

In this guide, we'll break down what bonded leather is, how it's made, its pros and cons, and practical tips for care. Whether you're designing wallets for budget-conscious customers or exploring synthetic leather options, this article will help you make informed choices and understand why bonded leather is a versatile material in the wallet-making industry.

What Is Bonded Leather?

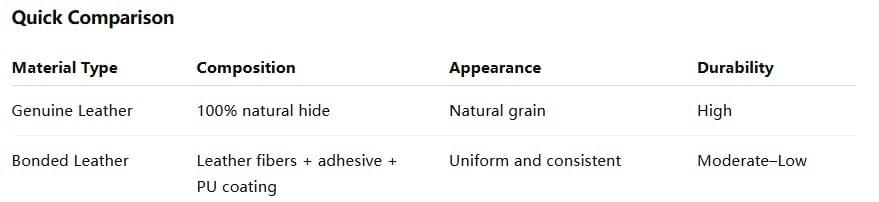

Bonded leather is a reconstructed material made by mixing leftover leather scraps with adhesive and adding a synthetic PU coating. It contains a small amount of real leather fibers but is reinforced with man-made layers, giving it a smooth, uniform surface that can resemble genuine leather.

For a wallet manufacturer, understanding the bonded leather definition is important because it can imitate the look of full-grain or top-grain leather, though its durability and aging performance are lower.

Bonded leather is cost-effective and visually appealing, making it suitable for entry-level wallets, but it won’t last as long as genuine leather.

How Bonded Leather Is Made

Bonded leather production follows a structured process designed to recycle leather waste while creating a uniform, visually appealing material. Understanding this process helps wallet manufacturers evaluate quality and determine whether bonded leather fits a specific product line.

Step-by-step process:

- Collection of Leather Scraps – Offcuts and leftover trimmings from leather factories are gathered.

- Shredding and Blending – These scraps are ground into fine fibers and mixed with a strong adhesive binder.

- Sheet Formation – The mixture is spread into a flat sheet and compressed to form a stable base.

- Surface Coating – A PU film or colored synthetic layer is applied to create texture, color, and grain patterns.

- Embossing & Finishing – Heat and pressure imprint natural leather-like patterns, giving the surface a premium look.

Because of this manufacturing method, bonded leather can mimic the appearance of genuine leather while offering consistent thickness and color—important for large wallet orders requiring uniformity. However, due to its layered structure, it does not age or patina like real leather.

How Bonded Leather Is Made

Bonded leather is produced by collecting leftover leather scraps, grinding them into fine fibers, and blending them with a strong adhesive. This mixture is then pressed into sheets to create a stable base. A synthetic PU coating is applied on top to add color, texture, and protection, followed by embossing to imitate the natural grain of genuine leather.

For a wallet manufacturer, this process results in a material that offers consistent thickness, color, and surface appearance — useful for mass production. However, because bonded leather is made from compressed fibers rather than a full hide, it lacks the natural durability, strength, and aging qualities of genuine leather.

Pros and Cons of Bonded Leather

Bonded leather offers a visually appealing and cost-effective option, which is why many brands use it for entry-level wallet collections. With its PU-coated surface, bonded leather provides a clean, uniform texture that closely resembles genuine leather. This consistency in color, thickness, and grain makes production easier for a wallet manufacturer, especially when handling large-volume orders. Its affordable price also makes it attractive for budget-conscious customers who still want a leather-like appearance.

However, bonded leather does not match the durability of genuine leather. Because it is made from compressed leather fibers rather than a full hide, it is more prone to cracking, peeling, and surface wear over time. It also lacks the natural breathability and aging characteristics that real leather offers, meaning it will not develop a patina or become softer with use. For high-end or long-lasting wallets, bonded leather is usually not the primary choice, but for promotional items, entry-level products, or designs that prioritize appearance over longevity, it remains a practical and economical material.

Conclusion

Bonded leather can be a useful material for budget-friendly wallets, offering a clean look and consistent surface at a lower cost. For a wallet manufacturer, it works well when appearance and price matter more than long-term durability. However, it cannot compete with genuine leather in strength, aging, or overall quality.

If your goal is to create entry-level or promotional wallets, bonded leather is a practical choice. If you want premium performance and long-lasting products, genuine leather remains the better option. Understanding the differences helps you choose the right material for your brand and customers.